What Is Piping Insulation and Why Does It Matter?

What Is Piping Insulation and Why Does It Matter?

Piping insulation might not be something you think about daily, but it plays an essential role in many industries. Whether it’s in your home, a factory, or an oilfield, insulation helps protect pipes, saves energy, and improves safety. Let’s explore piping insulation, why it’s important, and how it makes a big difference.

What Is Piping Insulation?

Piping insulation is a protective layer applied to pipes to control temperature, reduce energy loss, and prevent problems. This layer can be made from materials like foam, fiberglass, or rubber. Insulation is used for both hot and cold pipes, depending on the purpose.

Hot pipes need insulation to keep heat inside and avoid burns, while cold pipes use it to stop condensation and freezing. Proper insulation ensures that systems work efficiently and safely.

Why Is Piping Insulation Important?

1. Saves Energy and Money

Insulated pipes don’t lose heat or cold easily, which saves energy. This means less energy is needed to keep systems running at the right temperature. Over time, this can lead to lower utility bills for homes and businesses.

For example, a study found that insulating hot water pipes can save up to 10-20% on heating costs. In industries, the savings can be even bigger.

2. Prevents Damage to Pipes

Extreme temperatures can harm unprotected pipes. In winter, water in cold pipes can freeze and expand, causing the pipes to burst. Insulation prevents this by keeping pipes warm.

For hot pipes, insulation protects them from overheating, which can lead to cracks or leaks. This reduces repair costs and avoids interruptions to daily activities or business operations.

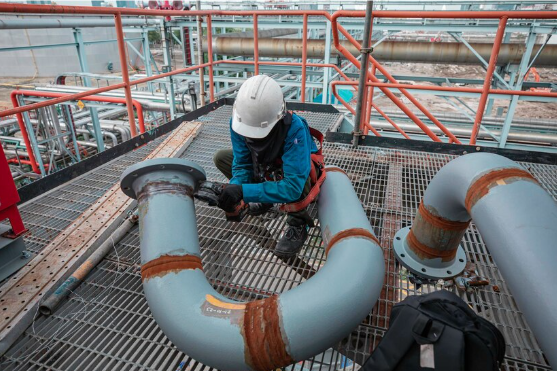

3. Improves Safety

Uninsulated hot pipes can be dangerous. If touched, they can cause burns or injuries, especially in places like factories or mechanical rooms. Insulation provides a barrier, making these areas safer for workers and visitors.

4. Reduces Noise

Did you know that pipes can be noisy? Water moving through pipes can create vibrations and sounds. Insulation dampens these noises, creating a quieter environment in homes, offices, and industrial settings.

Types of Piping Insulation

Different insulation materials are used depending on the needs of the system. Here are a few common types:

- Fiberglass Insulation: Known for its high-temperature resistance, it’s ideal for hot water pipes.

- Rubber Insulation: Flexible and great for both hot and cold pipes, especially in tight spaces.

- Foam Insulation: Lightweight and cost-effective, commonly used for home plumbing systems.

Each type has specific benefits, so choosing the right one depends on the application.

Where Is Piping Insulation Used?

Piping insulation is used in many places, including:

- Homes: To keep water pipes warm in winter and reduce energy costs.

- Factories: To protect workers and ensure efficient production.

- Oil and Gas: To maintain the temperature of fluids and prevent pipe damage.

Industries rely heavily on insulation to ensure safety and efficiency.

How to Choose the Right Insulation

When choosing piping insulation, consider these factors:

- Temperature Range: Ensure the material can handle the system’s temperature.

- Moisture Resistance: In humid areas, pick materials that won’t absorb water.

- Durability: Some environments require materials that resist wear and tear.

Consulting experts can help you find the best option for your needs.

Why Quality Matters in Piping Insulation

Proper installation and high-quality materials are essential for piping insulation to work effectively. Poorly installed insulation can leave gaps, causing energy loss and safety issues.

This is why many companies hire skilled professionals who are trained to handle insulation jobs. Using reliable services ensures the work is done safely and efficiently, saving you time and money in the long run.

The Bigger Picture

Beyond just saving energy and protecting pipes, insulation contributes to environmental sustainability. By reducing energy consumption, it lowers greenhouse gas emissions. This makes it a small but important step toward fighting climate change.

Frequently Asked Question

Q1. What is the purpose of piping insulation?

A: Piping insulation helps control temperatures, prevent energy loss, reduce noise, and protect pipes from damage like freezing or overheating.

Q2. What materials are commonly used for pipe insulation?

A: The most common materials include fiberglass, rubber, foam, and mineral wool. Each material is suited for specific temperature ranges and applications.

Q3. Can I install pipe insulation myself?

A: While small home projects might be manageable with DIY insulation kits, professional installation is recommended for larger or industrial systems to ensure safety and efficiency.

Q4. How does pipe insulation save money?

A: By reducing heat or cold loss, insulation lowers energy usage, which can significantly reduce utility bills for homes and businesses.

Q5. How often should pipe insulation be inspected or replaced?

A: Insulation should be inspected annually to check for wear, moisture damage, or gaps. Replacement may be necessary if the material is degraded or no longer effective.

Conclusion

Piping insulation is more than just a protective layer—it’s a vital part of keeping systems safe, efficient, and cost-effective. Whether in homes or large industrial projects, insulation prevents damage, saves energy, and ensures safety.

Investing in quality materials and expert installation is key. Reliable companies offer services like mechanical piping insulation, oilfield buildings, and scaffolding to ensure your systems work well and stay protected.

Don’t wait until problems arise. Contact a trusted provider today to learn how piping insulation can benefit you.