Flow & Release: Discover the Art of 스웨디시 Healing

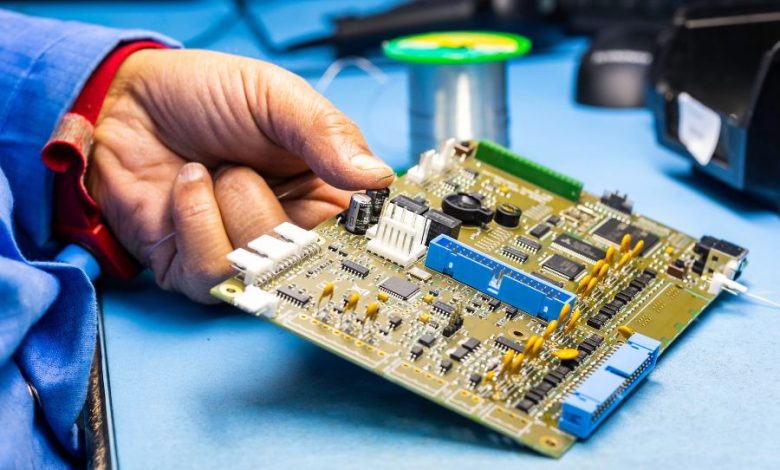

In today’s fast-paced electronics industry, speed and efficiency are everything—especially for startups. Whether you’re building the next big IoT device or a game-changing consumer gadget, getting your printed circuit board (PCB) prototype assembled quickly and accurately can make or break your product launch. That’s where prototype PCB assembly services come in.

For startups, these services offer a smart way to bring concepts to life without the heavy burden of time, cost, and technical complexity. In this article, we’ll explore the top 10 benefits of using prototype PCB assembly services and how partnering with a reliable PCB assembly company can accelerate your path to success.

1. Faster Product Development

Time is critical for startups. The quicker you can get your prototype ready, the faster you can move into testing, iteration, and production. Prototype PCB assembly services are designed to offer rapid turnaround, enabling you to test your design much sooner than if you were handling assembly in-house or outsourcing to a slower partner. This speed lets you meet investor timelines, capture market opportunities, and stay ahead of competitors.

2. Cost-Efficiency for Small Runs

Traditional PCB manufacturing processes are optimized for mass production, which isn’t ideal for startups that need only a few boards to begin with. Prototype assembly services specialize in small-batch or even single-unit production, offering a cost-effective way to build and test without committing to large volumes or high upfront costs.

3. Access to Advanced Equipment

Startups often don’t have access to the high-end equipment required for precision PCB assembly. By outsourcing to a professional PCB assembly company, you gain the benefit of cutting-edge machinery and tools—like SMT pick-and-place machines, reflow ovens, and X-ray inspection systems—without having to invest in them yourself.

4. Improved Design Validation

Before moving into full-scale production, it’s essential to validate the design of your PCB. Prototype services allow you to build a functional model of your board that can be tested for performance, reliability, and efficiency. Any flaws or inefficiencies can be identified and corrected early, saving you from costly rework or failures down the line.

5. Technical Expertise and Support

Many PCB assembly companies have engineering teams on hand to review your design files, suggest improvements, and troubleshoot issues. This expertise can be invaluable, especially if your internal team lacks experience in layout design, BOM optimization, or manufacturing tolerances. These experts can help ensure your design is both manufacturable and functional.

6. Reduced Risk of Manufacturing Errors

In-house PCB assembly without the proper equipment or experience can result in defects such as cold solder joints, bridging, or misaligned components. Prototype assembly services follow strict quality control standards, often including AOI (Automated Optical Inspection), functional testing, and X-ray inspection to ensure error-free delivery of your boards.

7. Flexibility in Iteration

Startups rarely get everything right on the first try—and that’s okay. Prototype services offer the flexibility to iterate quickly, allowing you to make changes and improvements without lengthy delays. This makes the prototyping phase a true development tool, not just a stepping stone to production.

8. Faster Time to Market

When your product development cycle is accelerated through efficient prototyping and reduced errors, your startup can reach the market faster. That means you can start generating revenue, gain customer feedback, and attract investors or partners earlier. Time-to-market advantage is crucial in competitive industries like wearables, automotive, or medical tech.

9. Customization and Specialization

Prototype PCB assembly services are typically more adaptable than full-scale production houses. They’re better suited for custom configurations, unique board shapes, or uncommon components. This level of specialization is important for startups working on innovative products that don’t fit the standard mold.

10. Focus on Core Competencies

By outsourcing the complex and technical task of PCB assembly, startups can focus on what they do best—developing, marketing, and refining their core product. Letting professionals handle the technicalities of assembly allows your internal team to remain agile, innovative, and focused on scaling the business.

Choosing the Right PCB Assembly Company

To fully realize these benefits, it’s important to choose the right PCB assembly partner. Here are a few quick tips:

-

Experience with Prototypes: Make sure the company has a proven track record with prototype and small-batch assembly.

-

Turnaround Time: Look for companies offering same-day or 24–72 hour turnaround options for prototyping.

-

Design Support: Companies offering DFM (Design for Manufacturability) checks can save you time and money.

-

Certifications: ISO and IPC certifications ensure quality standards are being met.

-

Customer Reviews: Check what other startups and engineers are saying about their services.

Final Thoughts

For startups navigating the early stages of hardware development, prototype PCB assembly services are more than just a convenience—they’re a strategic advantage. From cutting costs and saving time to improving product quality and reducing risks, these services offer immense value across the development cycle.

By partnering with a reputable PCB assembly company, startups can streamline their prototyping process, speed up innovation, and increase their chances of success in a competitive market.

Ready to bring your idea to life? Consider reaching out to a trusted prototype PCB assembly service today—and take the first step toward turning your vision into a working product.